Introduction to the Accucraft Ruby and its timing mechanism

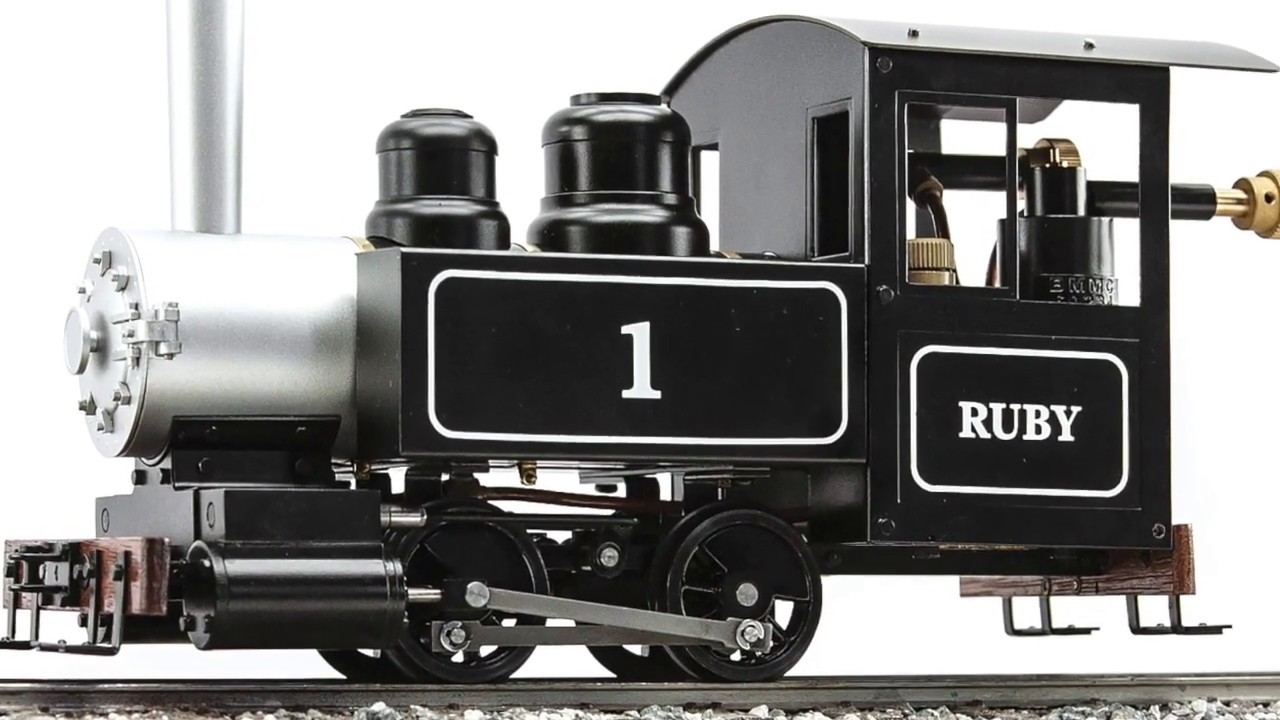

The Accucraft Ruby is a stunning piece of engineering that captures the hearts of model steam enthusiasts worldwide. Its intricate design and impressive performance make it a favorite among hobbyists who appreciate the art of steam locomotion. However, to keep your Ruby running smoothly, understanding its timing mechanism is essential. Proper timing ensures optimal efficiency and prevents potential issues during operation. Whether you’re a seasoned pro or new to the world of live steam trains, learning how to set the timing on an Accucraft Ruby can enhance your experience significantly. Ready to dive in? Let’s explore this fascinating process together!

How to Set the Timing on a Accucraft Ruby

Setting the timing on an Accucraft Ruby can significantly enhance its performance. This process is essential for achieving smooth operation and efficiency.

First, you’ll need to gather some basic tools. A screwdriver, a wrench, and a timing tool are vital for this task. Having everything at hand streamlines the process.

Next, accessing the timing mechanism involves removing specific parts of the engine casing. Take your time here; rushing could lead to damage or misalignment.

Once inside, using your timing tool allows for precise adjustments. Make small changes gradually to avoid overshooting your target setting.

After adjusting, it’s crucial to test the engine’s performance under various conditions. This ensures that everything runs smoothly without any hiccups along the way.

Fine-tuning might be required after testing. Regular maintenance will keep your Accucraft Ruby in top shape long-term.

Step 1: Gather necessary tools and materials

Before diving into the timing adjustment for your Accucraft Ruby, it’s essential to have all the right tools at hand. This will make the process smoother and more efficient.

Start with a basic toolkit that includes screwdrivers, preferably Phillips and flat-head types. These will help you access various components without damaging them.

Next, grab a timing tool or a dial gauge if available. This precision instrument is key for accurate adjustments.

You’ll also need some clean rags for any grease or oil spills during your work. Keeping everything tidy helps maintain focus on the task at hand.

Don’t forget safety glasses to protect your eyes from any potential debris while working on your engine. Having these materials ready sets you up for success as you move forward in perfecting your Ruby’s performance.

Step 2: Accessing the timing mechanism

To access the timing mechanism of your Accucraft Ruby, start by carefully removing any exterior panels. Most models have screws or clips that hold these parts in place. Use a suitable screwdriver to avoid stripping any fasteners.

Once the outer casing is removed, locate the timing mechanism. It’s usually situated near the engine’s valve gear and can be identified by its distinct shape and connection points.

Be cautious as you work around delicate components. If possible, refer to your model’s manual for specific guidance on accessing this area safely.

Ensure good lighting so you can clearly see what you’re doing; this will help prevent any unnecessary mistakes during adjustments. Taking your time here sets a solid foundation for proper tuning later on.

Step 3: Adjusting the timing using a timing tool

Now that you’ve accessed the timing mechanism, it’s time to make those precise adjustments. Grab your timing tool — this is essential for accurate modifications.

Place the timing tool onto the designated area of the mechanism. Ensure a snug fit; any slippage could lead to inaccurate settings. Turn the tool gently but firmly to adjust the gear position.

Watch closely as you tweak it. Small movements can make a significant difference in performance. Listen for changes in sound or rhythm; these cues are vital indicators of proper adjustment.

Keep checking back and forth to ensure everything aligns perfectly with your desired specifications. Patience is key here, so take your time to avoid overshooting your target adjustments!

Step 4: Testing the timing

After making your adjustments, it’s time to put the Accucraft Ruby to the test. Start by firing up the engine and observing its performance.

Pay attention to how smoothly it operates. A well-timed Ruby should run without stutters or unexpected stops. If you notice any irregularities, don’t panic; this is part of the tuning process.

Listen closely for sounds that indicate misalignment or timing issues. Unusual clinking or knocking can signal a need for further adjustment.

Take note of how responsive the locomotive is when applying throttle too. It should accelerate steadily and brake smoothly.

Run it through different speeds to see if adjustments hold under varying conditions. Keep an eye on any fluctuations in speed as this can give insights into whether additional tweaking might be necessary before moving forward.

Step 5: Fine-tuning and maintaining proper timing

Once you’ve tested the timing of your Accucraft Ruby, it’s time to fine-tune for optimal performance. Pay close attention to how the locomotive responds during runs. Minor adjustments can make a significant difference.

If you notice any hesitations or irregularities, revisit your settings. A slight tweak can enhance smoothness and power delivery. Use a timing tool for precision, ensuring every adjustment is small enough to avoid overcompensation.

Regular maintenance is crucial too. Dust and grime can affect performance over time. Keep the mechanism clean and lubricated; this will help maintain consistent operation.

Monitor your Ruby’s performance regularly after making changes. Consistency in timing directly impacts reliability on the tracks. The more frequently you check, the better your engine will perform in various conditions.

Cultivating a routine around these checks ensures that your locomotion experience remains smooth and enjoyable for years to come.

Conclusion

Setting the timing on an Accucraft Ruby is a rewarding task that can significantly enhance your model’s performance. Mastering this process not only improves efficiency but also extends the life of your locomotive.

With practice, each step becomes second nature. The satisfaction of seeing your Ruby run smoothly after fine-tuning is unparalleled.

Remember to regularly maintain and check the timing for optimal results. A well-timed engine runs quieter and performs better.

Embrace the journey of learning and adjusting as part of your hobby. Each small adjustment brings you closer to achieving perfection in your steam experience with the Accucraft Ruby.

FAQs

When it comes to setting the timing on an Accucraft Ruby, questions often arise. Here are some of the most common inquiries:

Q: What tools do I need?

A: To set the timing accurately, you will require a timing tool specific for your model. A screwdriver and possibly pliers might also be handy.

Q: How often should I adjust the timing?

A: It’s good practice to check and adjust the timing periodically or whenever you notice performance issues with your locomotive.

Q: Can I damage my Ruby by adjusting the timing?

A: If done carefully and according to instructions, there is minimal risk of damaging your engine. Always follow proper procedures when making adjustments.

Q: Is professional help necessary?

A: While many hobbyists successfully set their own timings, seeking professional assistance can provide peace of mind if you’re unsure about doing it yourself.

Q: Where can I find replacement parts if needed?

A: Authentic parts for Accucraft models are available at various hobby shops or directly from Accucraft’s website.

By understanding these aspects and following our step-by-step guide, you’ll feel more confident in tackling any timing issues with your Accucraft Ruby locomotives.